Work Processes

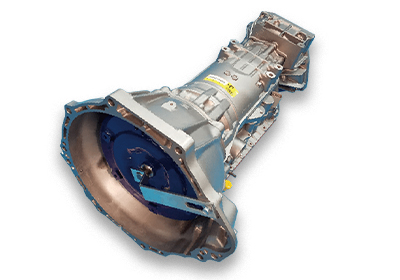

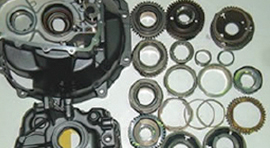

A/T Mission

works process-

01. Disassembly and cleaning After selecting parts, impurities are completely removed with a high-pressure washer.

-

02. Parts In addition to the basic replacement parts, all parts below the manufacturer's specification will be replaced with genuine parts. In addition, for parts that do not have a supply of genuine parts, we will use our original parts that are equivalent to genuine products.

-

03. Assembly We comply with the standard values in accordance with the work manual and assemble using measuring instruments and special tools.

-

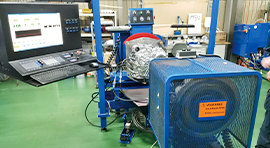

04. Testing State-of-the-art bench testers are used to perform consistent operational checks in automation. We will check the operating status with a monitor and ship the product that has cleared the standard value set inside the tester.

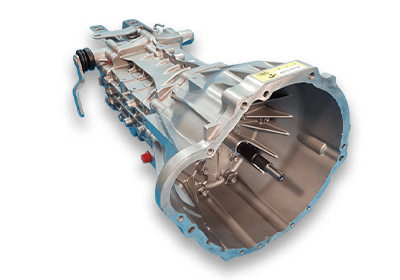

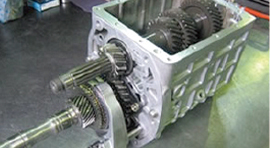

M/T Mission

works process-

01. Disassembly and cleaning Measure the specified value of each component, and remove parts below the specified value when disassembling the core. After that, the impurities are completely removed with a high-pressure washer.

-

02. Parts Basic replacement parts will be replaced with genuine parts. In addition, for parts that do not have a supply of genuine parts, we will use our original parts that are equivalent to genuine products.

-

03. Assembly Assembly and adjustment work is carried out by experienced professional staff who specialize in manual missions.

-

04. Testing After the assembly work is completed, the staff who produced the product and the chief staff conduct various operation tests using a dedicated tester, and only products that meet the standard values are delivered to the customer.

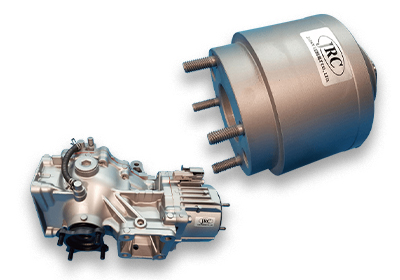

torque converter

works process-

01. Disassembly and cleaning The converter of non-degradable products is accurately disassembled by a special special machine, and the sludge and dirt inside are completely removed with a special cleaning solution.

-

02. Parts Components such as the lock-up paper base use parts jointly developed by the manufacturer, making it possible to rebuild the converter, which has a non-disassembling structure.

-

03. Assembly By using a specially designed automatic welding machine and welding with automation, it is reproduced with a consistent and high-quality finish without any welding omissions.

-

04. Testing Water pressure tests and balance tests are automatically performed with a dedicated measuring instrument, and only products that meet the standards are completed as products.

CVT Mission

works process-

01. Disassembly and cleaning Since dirt and sludge are often a major cause of failure of the components inside the mission, four large washing machines thoroughly clean four types of special cleaning solutions for each process.

-

02. Parts In many cases, the parts of the CVT transmission are not disassembled, and if there are no genuine parts, they will be rebuilt using original parts that are equivalent to the genuine parts.

-

03. Assembly The CVT transmission is non-disassembled, so there is no maintenance manual. We produce and assemble our own manuals based on our many years of experience.

-

04. Testing Once the CVT mission is completed, the performance of the mission is inspected by an automation machine with a built-in mission computer.

Differential Gear

works process-

01. Disassembly and cleaning The core is disassembled, reusable parts are detected, and impurities are completely removed with a pressure washer

-

02. Parts Genuine parts from each manufacturer are used, and if genuine parts are not supplied, original parts equivalent to genuine parts are used.

-

03. Assembly Carefully assemble while checking the oil clearance of the component parts

-

04. Testing The preload value of the bearing of the pinion gear and the backlash adjustment are adjusted within the specified values of each manufacturer using a special measuring instrument.

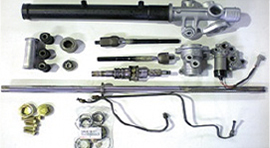

Drive Shaft

works process-

01. Disassembly After disassembling the shaft, we select a good core for each part while checking it.

-

02. Cleaning After sorting, grease and other deposits on each part are washed off by a high-pressure washer.

-

03. Shot After cleaning, the rust on each part is removed by spraying iron powder with a shot machine.

-

04. Correction machine Even the slightest distortion is corrected by the shaft correction machine to ensure quality.

-

05. Parts -

06. Assembly It is assembled by skilled technicians.

-

After cleaning (removing grease, etc.) -

After the shot (rust removed) -

After polishing (removing scratches, etc.)

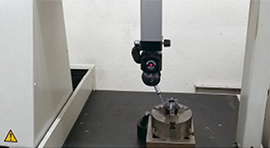

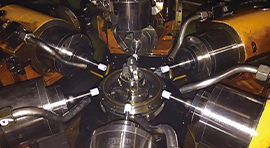

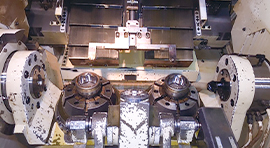

Outer Joints

works process-

01. Measurement A CMM is used to accurately determine the center position of the spherical surface and ball groove inside the outer joint.

-

02. Cage window frame polishing Depending on the standard, 6 windows of the cage are processed at the same time.

-

03. Lace groove polishing The ball grooves (6 places) of the inner lace are continuously polished according to the standard.

-

04. Joint groove polishing Continuous processing of two ball grooves (6 places) inside the joint is performed at the same time according to the standard.

* After polishing the joints, cage, and lace, the outer joint is completed by assembling three parts and a new ball.

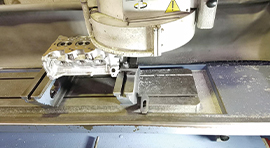

Steering rack and pinion

works process-

01. Disassembly and cleaning Impurities are completely removed by a special high-pressure washer, and details are cleaned by hand.

-

02. Parts Genuine parts from each manufacturer and parts that are not supplied by the manufacturer (bushings, etc.) use new parts produced in-house.

-

03. Assembly Replacement parts such as oil seals will be assembled with the utmost care.

-

04. Testing Complete inspection by an automation tester that can also inspect the inside of the control valve for hydraulic leaks. The monitor inspects the generated torque, operating status, etc. until completion.

Steering Vane Pump

works process-

01. Disassembly and cleaning The interior is cleaned completely with chemical chemicals so that no carbon, sludge, etc. are left behind.

-

02. Correction of camring processing The heart of the vane pump is a machine developed in-house, and the dimensional tolerances of each part are restored to a new product using advanced regeneration technology.

-

03. Valve Clearance Measurement Measure whether the oil clearance of the housing case and the flow control valve is within the specified values.

-

04. Testing All finished products are checked for hydraulic pressure, adjustable flow rate, and intrinsic discharge in each rotation range based on data from each manufacturer's standards.

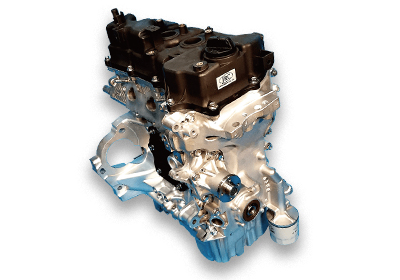

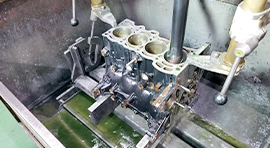

engine

works process-

01. Flat grinding The combustion chamber surface of the cylinder head is polished down to the micron level to correct distortions and scratches.

-

02. Crank Polishing The crankshaft is polished when oversized metal is assembled.

-

03. Honing (Bowling) When using an oversized piston, it is bored to an oversized piston. Even in the case of STD size, scratches on the cylinder bore are corrected by honing.

-

04. Adjustments The clearance of each part is adjusted and assembled based on the manufacturer's maintenance manual

-

05. Testing We conduct a 30 to 60 minute firing test for each unit, check for compression, oil pressure, abnormal noise, oil leakage, and coolant blowback, and inspect each bolt hole and port before shipping.

Catalytic converters, DPFs, SCRs

works process-

All gaskets will be replaced with new ones.

-

Even in non-disassembled car models, the filter is replaced.

Starter motor

works process-

01. Disassembly and cleaning The core is disassembled and the components to be reused are completely cleaned of impurities with a pressure washer.

-

02. Parts Bearings, brushes, contacts, and switches are basically replaced, and parts such as rotor shafts are inspected and sorted.

-

03. Assembly We check the tightening torque, shaft rotation, etc., and assemble while checking the standard values.

-

04. Testing The automation tester has built-in standard values from each manufacturer, and checks whether the rotation speed, torque value, and current value under load are satisfied.

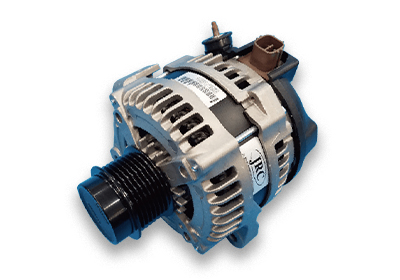

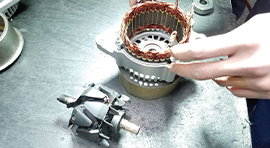

alternator

works process-

01. Disassembly and cleaning The core is disassembled and the components to be reused are completely cleaned of impurities with a pressure washer.

-

02. Parts We will generally replace the bearings and brushes, and inspect parts such as the IC regulator, rectifier, and stator coil, and replace them.

-

03. Assembly The rotor shaft and pulley are rotated, the brush contact is checked, and the assembly is performed at the specified torque.

-

04. Testing The automation tester has built-in standard values of each manufacturer, and checks whether the voltage and current values at low ~ high rpm are satisfied.

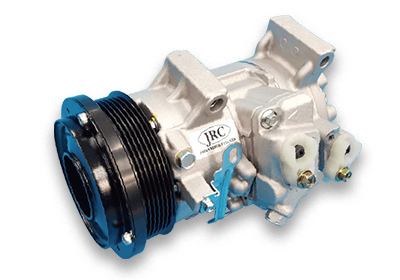

Air Conditioner Compressor

works process-

01. Disassembly and cleaning The core is disassembled and the components to be reused are completely cleaned of impurities with a special cleaning solution.

-

02. Parts Replace parts such as o-rings, gaskets, seals, bearings, and stator coils.

-

03. Assembly While checking the shaft for distortion and scratches, assembly is performed at the specified torque.

-

04. Testing The tester has a built-in condenser, receiver, exhaust, and evaporator, and the test is performed by reproducing the state mounted on the actual vehicle.

Viscous Coupling

works process-

01. Disassembly and cleaning The core is disassembled and the parts to be reused are completely removed from impurities with a high-pressure washer.

-

02. Parts The viscous coupling is non-disassembled, so there is no setting for genuine parts. We use original parts that are genuinely equivalent to those developed in collaboration with the manufacturer.

-

03. Assembly Carefully assemble while checking the oil clearance of the component parts.

-

04. Testing The adjustment of the preload value of the bearing is measured and checked by a dedicated tester for welding, oil leakage, etc.

If you can see it in the product catalog, or if you can see the products we handle with reliable quality, you can check it from the link below.